MITSUBISHI CNC System

E70 SERIES CNC Controls

The E70 CNC incorporates performance of M70V series as well as deploying screen configuration of M700V & M70V series.

KEY BENEFITS:

High Cost Effectiveness:-

- Very smooth cutting surface achieved with one-nanometer position interpolation.*

- Up to 20 sequence programs can be registered with the built-in PLC function.

- A wide array of development support tools such as NC Designer is available.

- Ultra-compact drive units with built-in power supplies contribute to reducing control panel size.

Compact Size and Less Wiring:-

- The control unit is integrated into the back side of the display to realize compact size.

- Ethernet* is available as standard specification, enabling input/output of machining programs and parameters by connecting the NC to a personal computer.

- Front CF card/USB memory interface in the display as standard specification.

- Analog output offered as standard specification to enable the use of a spindle drive with an inverter.

MITSUBISHI CNC Machine Operation Panel:-

- Simple to operate and configure

- The key layout can be customized according to machine specifications.

- Wiring has been reduced

KEY Functions:

- INCLINED AXIS CONTROL (LATHE SYSTEM)

- SPINDLE/C-AXIS CONTROL

- GUIDANCE FUNCTION

- SYSTEM LOCK FUNCTION

Applications:Lath and Milling machines.

C70 SERIES CNC Controls

The C70 CNC System is iQ Platform compatible provides maximum scale TCO reduction effects.

Main Features:

- Building Block Type

- Speed enhancement by high-speed bus between multi-CPUs

- Multi-axis and multi-part system

- Safety observation function

- GOT1000 Series

Benefits by Technology:

- Enhanced Productivity by; reduced tact time and operation efficiency enhancement

- Reduced Maintenance; & reduced downtime, early identification of failure causes and reduction in maintenance cost

- Design & Development: shorten design and development period

- Safety Standards; confirming to EN ISO13849-1 PL d

- Energy Saving ; saves energy and maximize productivity

Key Features:

Enhancement of operations through Automation:

- Tool life management

- Tool Radius compensation

- Tool length measurement

- Nose R compensation

Reduced Maintenance | less Downtime:

- No Fan in Control Unit;Fans inside C70 control module have been removed, as cooling is executed by radiator fin.

- Enhanced oil-resistance in drive unit

- Back-up/Restore function

High Speed Networking:

- High speed bus between CNC CPU and PLC CPU

- A high speed speed cycle between high speed shared memories of each CPU

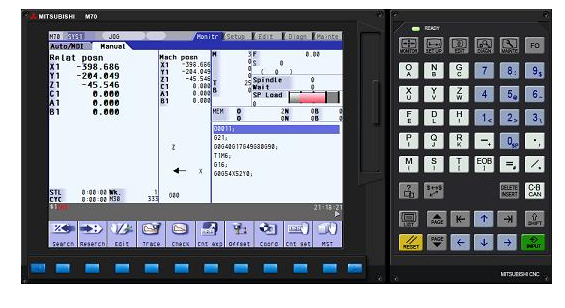

M70V SERIES CNC Controls

The M70V is further progress to the new MITSUBISHI standard CNC control systems.

Key Features:

- Higher-grade CNC performance attained.

- Basic Performance

- Multi-part Systems Multi-axis

- Nano Control

Operation Features:

- High speed

- High accuracy

- Multi Axis Control

- Easy Operation

- Remarkable reduction in cycle time

- High grade CNC performance attened

- Useful functions for combined machining

Applications:

- Machining Center system

- Lathe System

- Tapping Machine

- Milling enabled Lathe

- Compound multi axis lathe

M700V SERIES CNC Controls

Mitsubishi M700V Series CNC systems are designed for top level machine performance.

Mitsubishi’s CNCs with complete high-speed nano-control basic Performance and Function

- Complete Nano Control

- PLC Axis

- Index Modification Function of PLC Instructions

Key Functions and Configuration:

- SSS Control

- R-Navi

- Multi-part System Multi Axis

- Hobbing

- Milling Interpolation

- Balance Cut

- Memory Card/USB interface

- CC-Link networking

- Ethernet communication